新聞中心

高精度滾珠絲杠的保養(yǎng)方法

來源:http://www.baoxianyingxiao.cn/ 日期:2023-06-17 發(fā)布人:

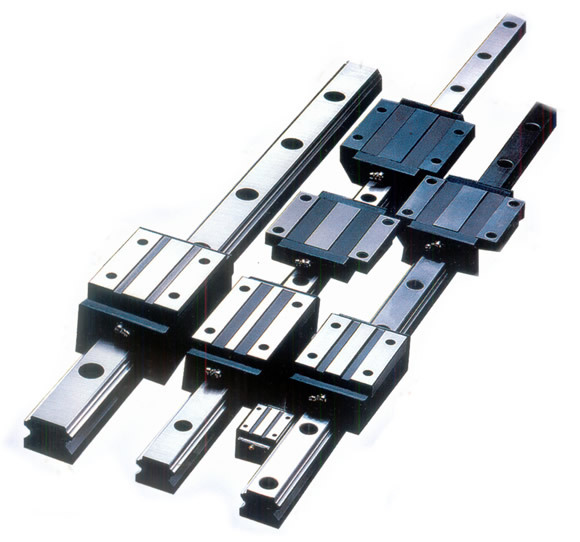

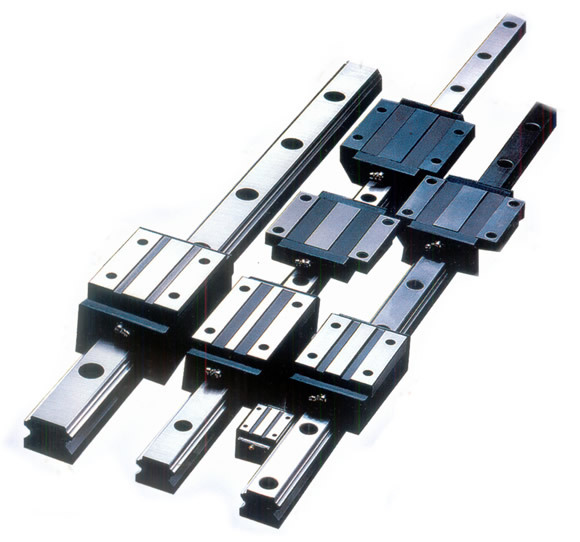

高精度滾珠絲杠是由導(dǎo)軌、絲杠和螺母組成的,絲杠和螺母之間通過滾珠傳動(dòng)實(shí)現(xiàn)轉(zhuǎn)動(dòng)。在滾珠的作用下,絲杠和螺母之間的摩擦力得到了大大的降低,從而使高精度滾珠絲杠具有高精度、高速度、高負(fù)載能力等特點(diǎn)。下面導(dǎo)軌絲杠廠家來講講高精度滾珠絲杠的保養(yǎng)方法。

The high-precision ball screw is composed of a guide rail, a lead screw, and a nut, and the rotation between the lead screw and the nut is achieved through ball transmission. Under the action of the ball, the friction force between the screw and the nut is greatly reduced, resulting in high-precision ball screws with characteristics such as high precision, high speed, and high load capacity. Below, the guide rail screw manufacturer will talk about the maintenance methods of high-precision ball screws.

1、定期檢查

1. Regular inspection

高精度滾珠絲杠在使用過程中需要定期檢查,檢查內(nèi)容包括:

High precision ball screws require regular inspection during use, including:

(1) 檢查導(dǎo)軌和絲杠的表面是否有劃痕或損傷;

(1) Check the surface of the guide rail and screw for scratches or damage;

(2) 檢查滾珠的狀態(tài)是否正常,是否存在磨損或缺失;

(2) Check whether the ball is in normal condition, worn or missing;

(3) 檢查螺母的狀態(tài)是否正常,是否存在磨損或變形等現(xiàn)象。

(3) Check whether the nut is in normal condition and whether there is wear or deformation.

定期檢查可以及時(shí)發(fā)現(xiàn)高精度滾珠絲杠的問題,防止出現(xiàn)嚴(yán)重的故障。

Regular inspections can promptly identify problems with high-precision ball screws and prevent serious malfunctions.

2、清洗和潤(rùn)滑

2. Cleaning and lubrication

高精度滾珠絲杠的清洗和潤(rùn)滑是非常重要的保養(yǎng)措施。在清洗和潤(rùn)滑時(shí)應(yīng)注意以下幾點(diǎn):

The cleaning and lubrication of high-precision ball screws are very important maintenance measures. The following points should be noted during cleaning and lubrication:

(1) 清洗時(shí)使用無紡布或棉布擦拭,不要使用含有酸堿等腐蝕性物質(zhì)的清潔劑,以免損壞部件;

(1) When cleaning, use non-woven cloth or cotton cloth to wipe, do not use detergent containing Corrosive substance such as acid and alkali, so as not to damage parts;

(2) 潤(rùn)滑時(shí)應(yīng)使用高質(zhì)量的潤(rùn)滑脂,根據(jù)使用條件和環(huán)境選擇適當(dāng)?shù)臐?rùn)滑脂;

(2) When lubricating, high-quality lubricating grease should be used, and appropriate lubricating grease should be selected according to the usage conditions and environment;

(3) 潤(rùn)滑時(shí)應(yīng)注意潤(rùn)滑脂的用量,過多或過少都會(huì)影響高精度滾珠絲杠的性能;

(3) When lubricating, attention should be paid to the amount of lubricating grease, as too much or too little can affect the performance of high-precision ball screws;

(4) 潤(rùn)滑脂應(yīng)定期更換,避免過期或變質(zhì)。

(4) Lubricating grease should be replaced regularly to avoid expiration or deterioration.

3、避免超載和長(zhǎng)時(shí)間空載運(yùn)行

3. Avoid overloading and long-term no-load operation

高精度滾珠絲杠在使用時(shí)需要注意避免超載和長(zhǎng)時(shí)間空載運(yùn)行,因?yàn)檫@會(huì)導(dǎo)致高精度滾珠絲杠的壽命縮短或者出現(xiàn)故障。

When using high-precision ball screws, it is necessary to pay attention to avoiding overloading and long-term no-load operation, as this can shorten the lifespan of high-precision ball screws or cause malfunctions.

4、避免振動(dòng)和沖擊

4. Avoiding vibration and shock

振動(dòng)和沖擊是高精度滾珠絲杠易受到的影響,會(huì)導(dǎo)致滾珠、絲杠、螺母等部件的損壞或磨損。因此,在使用高精度滾珠絲杠時(shí),應(yīng)該盡量避免振動(dòng)和沖擊。

Vibration and impact are easily affected by high-precision ball screws, which can cause damage or wear to components such as balls, screws, and nuts. Therefore, when using high-precision ball screws, vibration and impact should be avoided as much as possible.

在高精度滾珠絲杠沒有使用時(shí),應(yīng)該進(jìn)行妥善的儲(chǔ)存和保護(hù)。一般來說,應(yīng)該將高精度滾珠絲杠放置在干燥、清潔、無灰塵的地方,避免陽(yáng)光直射和雨水浸泡。在儲(chǔ)存時(shí),應(yīng)該將高精度滾珠絲杠用塑料袋包裝好,避免灰塵和腐蝕物質(zhì)的侵蝕。更多相關(guān)事項(xiàng)就來我們網(wǎng)站http://www.baoxianyingxiao.cn咨詢吧!

When high-precision ball screws are not in use, they should be properly stored and protected. Generally speaking, high-precision ball screws should be placed in a dry, clean, and dust-free place, avoiding direct sunlight and rainwater immersion. When storing, high-precision ball screws should be packaged in plastic bags to avoid erosion by dust and corrosive substances. For more related matters, come to our website http://www.baoxianyingxiao.cn Consult!