新聞中心

滾珠絲桿運(yùn)行不順和油潤(rùn)滑的介紹

來源:http://www.baoxianyingxiao.cn/ 日期:2021-01-29 發(fā)布人:

1、這是造成TBI滾珠絲桿運(yùn)行不順暢的其中一個(gè)原因,這點(diǎn)原因分兩種情況:

1. This is one of the reasons why TBI ball screw does not run smoothly

(1)由于在出貨時(shí),許多的包裝材料和防鋪袋包裝滾珠螺帽,螺桿在包裝或者排列鋼珠的時(shí)候沒有一次適當(dāng)?shù)臉?biāo)準(zhǔn)程序來完成執(zhí)行,異物或者其他的一些碎物等雜物就會(huì)堵住鋼珠軌道,造成由包裝材料堵住軌道從而影響滾珠絲桿的運(yùn)行。

(1) Due to the fact that there is no proper standard procedure to complete the execution of many packing materials and anti laying bag packing ball nuts and screws when packing or arranging the steel balls, foreign matters or other debris will block the ball track, causing the packing materials to block the track, thus affecting the operation of the ball screw.

(2)可能就是TBI滾珠絲桿安裝時(shí)如果沒有配置刮刷器,那么在加工的時(shí)候,加工碎屑和灰塵就很容易進(jìn)堆積在軌道,堵住鋼珠軌道,從而造成滾珠絲桿運(yùn)行不順暢,精度降低和縮短壽命。

(2) It may be that if the TBI ball screw is not equipped with a wiper when it is installed, the processing debris and dust will easily accumulate in the track and block the ball track during processing, which will cause the ball screw not to run smoothly, reduce the accuracy and shorten the service life.

2、螺母在安裝的時(shí)候傾斜或者偏心,會(huì)造成絲桿異常負(fù)載,使得馬達(dá)運(yùn)轉(zhuǎn)時(shí)產(chǎn)生電壓不穩(wěn)定。搬運(yùn)時(shí)造成TBI滾珠絲桿的損壞。

2. When the nut is tilted or eccentric during installation, it will cause abnormal load of the screw rod, which will cause voltage instability when the motor is running. TBI ball screw is damaged during handling.

3、TBI滾珠絲桿在運(yùn)行過程稍有不當(dāng)會(huì)造成回流管的損壞和凹陷,導(dǎo)致滾珠無法正常運(yùn)轉(zhuǎn),從而導(dǎo)致螺桿或者螺帽珠槽表面剝離。

3. A little improper operation of TBI ball screw will cause damage and depression of the return pipe, which will lead to the ball not working normally, resulting in the surface peeling of screw or nut groove.

4、軸承的安裝不正確也是造成滾珠絲桿運(yùn)行不順暢的一個(gè)原因,螺桿或者螺帽珠槽表面粗糙,鋼珠大小或者硬度不均勻,回流管組裝不正確等等都能使絲桿在運(yùn)行過程中產(chǎn)生障礙。

4. The incorrect installation of the bearing is also one of the reasons for the unsmooth operation of the ball screw. The rough surface of the screw or nut groove, the uneven size or hardness of the steel ball, and the incorrect assembly of the return pipe can cause obstacles in the operation of the screw.

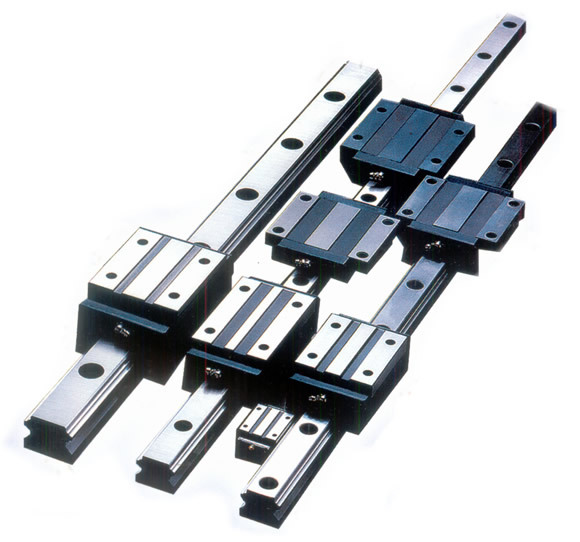

油潤(rùn)滑要預(yù)先在密封型導(dǎo)軌中充填潤(rùn)滑油脂的密封方式,以及在外殼內(nèi)部填充適量的潤(rùn)滑油脂,每隔一段時(shí)間進(jìn)行補(bǔ)充或更換的填充供脂方式。

For oil lubrication, the sealing method of filling grease in the sealed guide rail in advance, and the filling and grease supply method of filling proper amount of grease in the shell and replenishing or replacing at intervals are required.

此外,對(duì)有多處滑軌需要潤(rùn)滑的機(jī)械,還采用管道連接各潤(rùn)滑處的集中供脂方式。脂潤(rùn)滑可做到填充一次潤(rùn)滑油脂后長(zhǎng)時(shí)間不需要補(bǔ)充,而且其密封裝置的結(jié)構(gòu)也較簡(jiǎn)單,因此使用廣泛。油潤(rùn)滑相對(duì)來說比較簡(jiǎn)單,經(jīng)常潤(rùn)滑能大大提升直線導(dǎo)軌的使用壽命及保持一定的精度和預(yù)壓。

In addition, the centralized grease supply mode with pipes connected to each lubrication place is also adopted for the machinery with multiple sliding rails needing lubrication. Grease lubrication can be filled with grease for a long time without supplement, and the structure of its sealing device is simple, so it is widely used. Oil lubrication is relatively simple, regular lubrication can greatly improve the service life of linear guide and maintain a certain precision and preloading.